Zone Control

How Does Zone Control Work

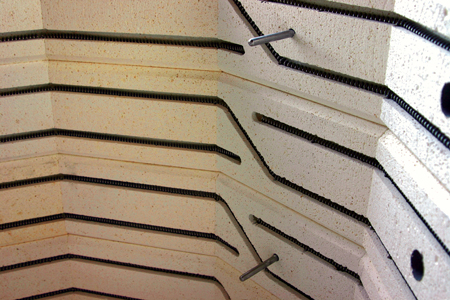

Zone Control kilns have a thermocouple in each section of the kiln and cycle the power to each section on and off semi-independently as if it were an individual kiln. For example, lets say you have have a 3 section kiln and the bottom section is firing a little cooler than the middle and and top section. With zone control turned on, the controller will turn off power to the middle and top sections until the bottom section has caught up and then turn the power to all 3 sections back on. This ensures that the temperature difference between the sections never gets to great.

Zone Control cannot easily be added later since it requires the changing of several internal components therefore it is suggested that you add it when you order your kiln. It is not available as an upgrade on all models. The reason for this is that the kiln needs to have a minimum power rating known as the loss to watt ratio in order for the kiln to keep up with the program when sections are turned off to balance the temperature. Consult your distributor to find out if zone control is available for your desired model. You may also use the Build A Kiln web tool to find out if it is available.

Pros and Cons

Zone control is not recommended for all applications. Like many things in life, there are pros and cons to zone control. We computer balance all of our elements. Kilns lose most of there heat through the lid and the slab. This is why we use hotter elements in the top and bottom of the kiln and cooler elements in the center. This makes most of our kilns fire extremely even without the need for zone control. There are times however when you need the exact control Zone Control can offer.

Pros

- More Even Firing Top To Bottom – Often necessary when firing very tall pots or working with extremely sensitive material like thick glass projects.

- Your Friends Will Think You Are Really Cool – Do not discount this. Your cool factor will go up like 10 fold.

Cons

- Longer Firing Times – Because the elements need to cycle off more to retain uniformity, your firing times will be extended.

- Shorter Relay Life – Standard relays (Not Mercury relays which are standard on all PK kilns) will cycle more often and therefore have a shorter life.

- More Thermocouple Maintenance – Well, there are 3 so you do the math. It is really important to use cones in every firing to monitor the accuracy of the thermocouples. If one starts to go before the others it can actually make Zone Control fire your kiln UNEVEN.

- Shorter Element Life – At high temperatures it can be difficult for the elements to keep up with the program when they start to wear. Therefore you will most likely get an error message that shuts down the firing sooner in the life of the elements then if you did not have Zone Control. You can turn Zone Control off and milk a little more life out of them.

- More Difficult to Diagnose Problems – Since more is going on during the firing often times it makes troubleshooting more difficult but not impossible