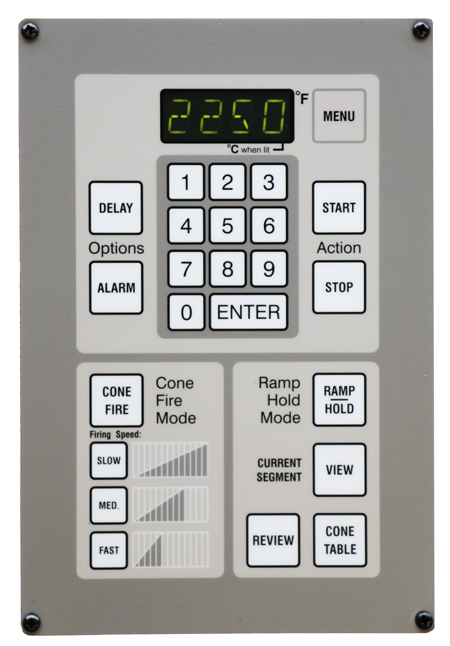

The KilnMaster Controller

We Make It Easy

Whether you are doing a simple bisque firing or programming your own 10 segment program, the KilnMaster controller is intuitive and easy to use. We spent a lot of time designing a layout that allows access to all the features efficiently. Even if you have never programmed a kiln before you will feel like an expert in no time at all.

If you get stuck and don’t know what to do next, watch the video. Every feature and process has a video located online which will walk you through it step by step. Still stuck? Give us a call and we will walk you through it over the phone. Out technicians are available 5 days a week from 7:30 in the morning to 5:00 at night PST.

Packed with Useful Features

All the features you could possibly want are in this controller:

ConeFire Mode

With ConeFire Mode you just enter 4 pieces of data Preheat Time, Cone Value, Firing Speed, and Peak Temperature Hold Time. The controller then chooses a program for you that was designed by ceramic engineers for optimum results. It even has Cone Correlation built in that will adjust your ending temperature up or down based on the kilns performance to ensure the perfect amount of heatwork.

The Preheat feature gives you the option to preheat your unfired pieces to make sure there is no residual moisture in the clay that can cause damage to the ware.

You can even turn on a feature now that lets you add a slow cooling ramp to your firing schedule that produces interesting glaze effects. It is appropriately named the COOL feature.

Ramp and Hold Mode

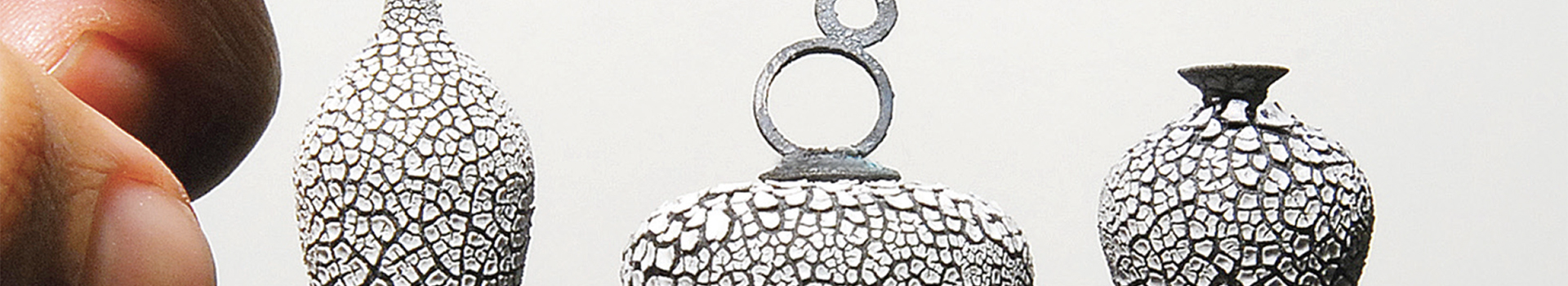

Ramp/Hold mode lets you design your own firing programs of up to 32 segments. Each segment can include temperature rate, end temperature and holding time. You can store up to 12 profiles for easy recall. These capabilities are essential for potters, glass fusers, enamellists and jewelers. For example, it is now easy to program crystal glaze pottery firings which require long, precise soaks while cooling.

You can now benefit from the Cone Correlation feature previously only found in ConeFire Mode by pressing the Cone Table key when asked to enter your peak temperature. This allows you to enter a cone value instead of temperature. The controller will then adjust the ending temperature down automatically to ensure proper heatwork no matter how slow your kiln is firing.

The example below shows a typical Ramp/Hold profile for a Cone 10 crystal glaze firing.

Delay Start

Delay start was developed for people who want to fire overnight but do not want to get up in the middle of the night to ensure their kiln shut off okay. You just enter a delay time and the controller will begin counting down the time entered. When it reaches zero it will start the program you have entered.

Temperature Alarm

The temperature alarm can be convenient if there are specific temperatures at which you wanted to be alerted. For example, you may want to set it for 1000F to remind you to lower your lid if you are venting a kiln without a downdraft vent.

Calculate Firing Costs

Yes really! This controller will tell you how much your firing cost you after every firing. All you need to do is follow the manual instructions for entering your cost per Kilowatt hour and the wattage rating of your kiln.

Automatically Start Vent

The controller has an additional output on the circuit board which allows you to connect to our EnviroLink. The EnviroLink is an optional accessory that works in conjunction with the EnviroVent 2. When installed it will automatically start the vent when you press start and turn it off when the kiln has cooled to 150F.

Fire in Fahrenheit or Celsius

Set the display to read in Fahrenheit or Celsius.

Built-in Cone Table

A convenient Cone Table button is available for reference to find the temperatures associated with various cone values.

Tracks Total Number of Firings

Being able to track the number of firings is extremely valuable when you are keeping a kiln log. It allows you to record whenever you change elements, relays and thermocouples. This way you can better predict when you might be ready for some maintenance. It will give you this value after every firing.

Best Diagnostics

Skutt is one of the only companies that installs a Current Sensor in the control box. This allows us to test the electrical performance of your kiln without even having to open the box. We can walk you through it on the phone and get all the information we need to diagnose your kiln and get you up and running again.

Voltage Test

Amperage Test

Error Temperature

Board Temperature

Much more…