Type S Thermocouple

Most all of the kilns that leave are factory are equipped with a Type K thermocouple. Type K thermocouples are accurate and inexpensive. The down side to Type K thermocouples is that they wear out and they wear out faster when exposed to extreme conditions. Type S thermocouples can virtually last forever. The reason for this is that they are made of platinum which does not degrade under most atmospheres and has an extremely high melting point. This leads us to one of their downsides, they are expensive…BECAUSE THEY ARE MADE OF PLATINUM!!!

They are mostly in scientific settings and when they are constantly exposed to harsh environments like those that Crystal Glaze Artists expose them to. I know what you are thinking “If I go ahead and upgrade now, it should pay for itself over the life of the kiln from not having to replace thermocouples”. That may be true…if you don’t break it. Because it is made of very expensive Platinum, the wire used to construct the thermocouple is very, very thin. On top of this, it is housed in a fragile high alumina cover. If you hit it with a shelf, it’s game over. If you do make the upgrade, you may become the full time kiln loader if you are not already.

How to Upgrade

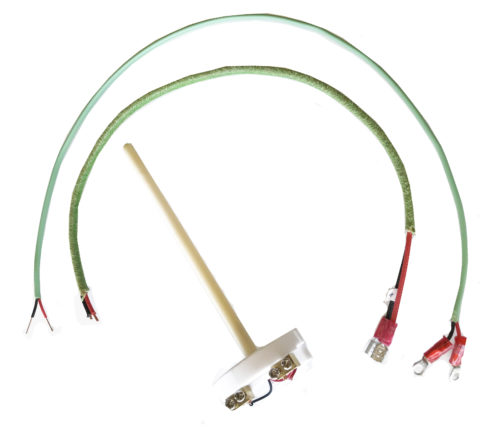

When you change from a Type K thermocouple you need to do several things:

- Change ALL of the thermocouple wire to Type S thermocouple Wire. Their should be two pairs of positive and negative wires; one going from the thermocouple block to the kiln side of the terminal strip and the other going from the backside of the terminal strip to the controller.

- Change the setting on your controller to the type S position. If you cannot reconfigure your controller you may need to invest in a new one. All Skutt controllers are configurable but depending on the age, the process can be different.

If you fail to do either of these two things your kiln could severely over fire.