Current Sensing

Traditionally, when your kiln is not firing correctly, it is necessary to open the control box and take some electrical readings to diagnose the problem. Since most people do not have the test equipment or are not qualified to take live electrical readings from a kiln, this usually requires hiring a trained technician to come out and diagnose the problem. This can take time to schedule and cost a significant amount of money.

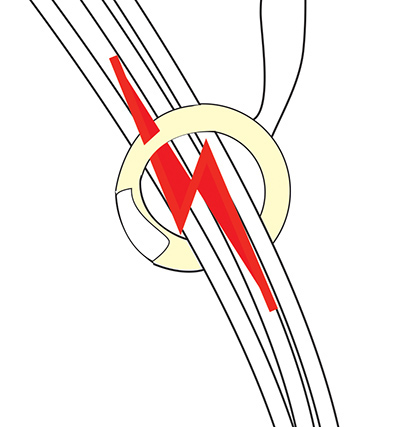

Skutt is one of the few companies that installs that technician right in the kiln in the form of a Current Sensor. A current sensor is a small donut shaped device that can read current (Amperage) when one leg of a circuit is passed through it.

Being able to sense current is one of the best tools for diagnosing your kiln and this tool is accessed easily from the Menu key on your controller. This allows you to provide your service technician the information he or she needs without having to make an additional service call. This way they can order the needed parts and come out once to install them.

The circuit board can also check the voltage supply powering the kiln. It firsts checks it with a the kiln drawing power. This will tell you if the supply matches the voltage for which the kiln was designed. It then measures the voltage with the kiln own. This can indicate problems with the electrical installation from the breaker box to the outlet. If the voltage drops significantly when the kiln is turned on it can be an indication that the wire gauge is not adequate given the draw of the kiln or the distance from the breaker box to the outlet.