What is the Orton Cone Chart?

The Orton Cone Chart was developed by Edward Orton, Jr. in the late 1800s. It is based on the use of Pyrometric cones to measure heatwork in a kiln firing. Prior to their development there was no scientific means for indicating when to stop a kiln firing for optimal maturation of a clay body or glaze.

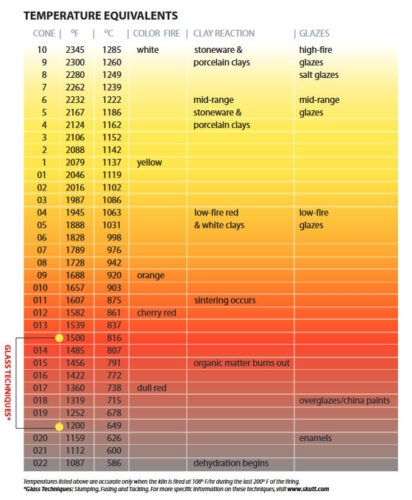

Skilled kiln tradespeople would have to judge the heat by the color of the light emanating from holes in the kiln called bung holes (referred to as peep holes in the USA for obvious reasons). As shown in the chart below, as the temperature in the kiln rose, the color would move from red to yellow to white.

They are composed of materials which are carefully measured and compressed into the shape of a tetrahedron. The cones are placed in the kiln on a shelf with your ware and, when they have received the proper amount of heatwork, they bend over indicating that it is time to turn off the kiln. Pyrometric Cones come in a variety of shapes and sizes. Each size and shape has a different temperature chart associated with it. The chart below is based on a Large Self-Supporting Cone and has become the standard for commercial clay bodies, glazes and controller software. All clay bodies and glazes are designed to fire to a certain cone value or range.

It is important to know that heatwork is the measurement of the effects of time and temperature. Just like with cooking a brisket or roast, the time you take to get to temperature and the amount of time you hold at that temperature will affect the results. For example, if you heated a brisket to the recommended 250 °F and then instantly shut off your oven, the brisket would be raw. Conversely if you brought your brisket to 250 °F and then held it there for 2 days, the brisket would be burned. The same concept holds true with ceramics.

The cone values listed in the chart are only valid if the kiln is firing at exactly 108 °F/hr. during the last 200 °F of the firing. This ensures that time is taken into account when calculating when the kiln shuts off. If you go faster, you will underfire the ware. If you go slower, or hold to long at that temperature, the ware will be overfired.

That is why it is very important to know the capabilities of your kiln when writing your own programs. As a kiln ages, it may begin to fire slower as the elements begin to wear out. Most controllers have a firing mode that compensates for this. In Skutt Controllers it is called ConeFire Mode. If the kiln is firing slower than 108 °F/hour it has built in algorithms that calculate a lower temperature for the kiln to shut off and thus attain the proper amount of heatwork.

We recommend that you still use Self Supporting Witness cones on every firing to monitor the accuracy of your kiln. Place the appropriate cone on a shelf approximately 2 inches from the kiln wall and two inches from the tip of the thermocouple and point the cone toward the center of the kiln chamber. Make sure the space between the thermocouple and cone is unobstructed.

We’ve included our Skutt Orton Cone Chart as a .pdf to view, download, or print below. And if you’re interested in learning more about all things pottery, check out our ceramic blog for valuable knowledge.

Leave a Reply

Want to join the discussion?Feel free to contribute!