The Motor

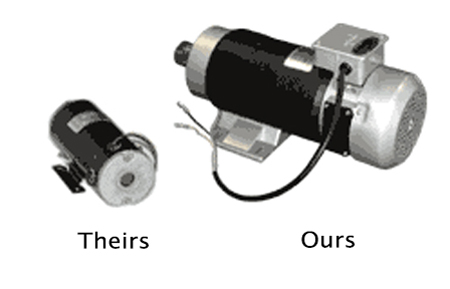

Skutt is the only company we know of that uses a Continuous Duty motor. These motors are tested under much more rigorous conditions so they need to be built tougher. That means heavy duty components that can stand up to the strain students (and big pot potter’s) can subject them to. Sometimes bigger is better.

Okay, where do we start. Probably the best place to start is to talk about torque at the wheel head. For years wheel companies have been trying to one up each other on “how much clay their wheel can center”. The bottom line is, horsepower is horsepower. The amount of torque you can produce at the wheel head is related to horsepower. Other factors, like controller settings, pulley size and belt slippage, can affect how you maximize this torque, but they cannot increase it. We use a 6 V-groove belt which gives us a lot of surface contact and prevents slippage. We will get into controller settings later.

Electric motors are rated as Continuous Duty or Intermittent Duty. A continuous duty motor has been tested under a load with the assumption that it is going to be under that load “continuously”. The motor is tested under a load until the temperature of the motor reaches thermal equilibrium (the temperature quits rising), and the components remain undamaged. Non-Continuous Duty motors are tested under load for short periods of time with the assumption that these motors will be used in settings where the loads will be very brief (a few minutes). Since our Continuous Duty motors need to withstand a tougher test, they need to be stronger and have more robust components to pass. That means heavier windings, larger brushes, stronger magnets…that is why when you look at our motors side by side with the competition, you can see they are much bigger.

Since our components are over-sized they stay cool and therefore last longer. There is even a built-in fan to provide more cooling to the motor.

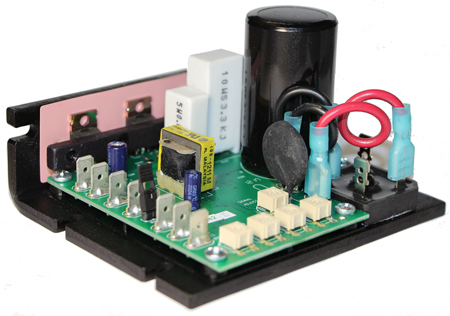

Ok so let’s talk controllers. As I mentioned before, heat is the ultimate culprit when comes to wearing out electrical components in your motor, the same goes with your controller. Our controller is much larger than most of our competitors because, again, we use larger more robust components that do not overheat.

People are always talking about how smooth our motors run. One reason for this is how we adjust the setting on the controller in the factory. We turn the torque setting all the way up (because it can handle it) and most importantly, we turn something called IR Comp completely off. IR Comp is a controller function that attempts to keep the wheel head speed consistent when you apply resistance (throwing or centering large amounts of clay).

People are always talking about how smooth our motors run. One reason for this is how we adjust the setting on the controller in the factory. We turn the torque setting all the way up (because it can handle it) and most importantly, we turn something called IR Comp completely off. IR Comp is a controller function that attempts to keep the wheel head speed consistent when you apply resistance (throwing or centering large amounts of clay).

In our research we found that most potters want to control this themselves by pressing on the foot pedal. It gives them a sense of control as opposed to having the controller doing this for them. It’s kind of an intuitive Zen relationship you develop with your wheel. One of the problems with IR Comp is the adjustments are not completely instantaneous (kind of like a beginning potter). You can feel a slight surge when you apply pressure to the wheel as the IR COMP kicks in and sends more voltage to the motor, likewise, when you release the pressure (take your hands off the clay) the wheel head can feel like it is accelerating until the controller can react. This can really wreak havoc on a large platter or pot. If for some reason you would like to have the controller make these decisions for you, let us know and we will tell you how to adjust the settings.