KM-1627-3PK

Home > Ceramic Kilns > KM-1627-3PK

Big Done Right

An Engineered Ceramic Fiber Lid and Fiber Insert are just a few of the things that make this kiln the most sophisticated oval production kiln on the market. Whether you are producing custom tile or large sculptures, this is the kiln for you.

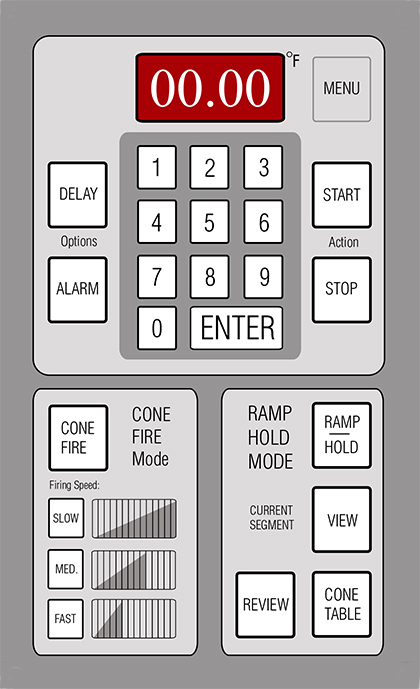

Sophisticated, Yet Easy to Use

- Write your own firing programs with up to 32 Segments using Ramp and Hold. Now you can store up to 12 programs.

- … or use the tried and true factory set programs in ConeFire Mode

- Built in Diagnostics give you or our technicians the ability to diagnose kiln problems with just a few button presses.

- New Safety Features help prevent accidental starts and overfires.

- New software keeps track of your Firing Costs and the Number of Firings

- Fuse Glass, Slow cool Cone 6 Glazes, Grow Crystals…whatever you want to program this controller can handle.

- …and so much more. Click Here to see the whole story.

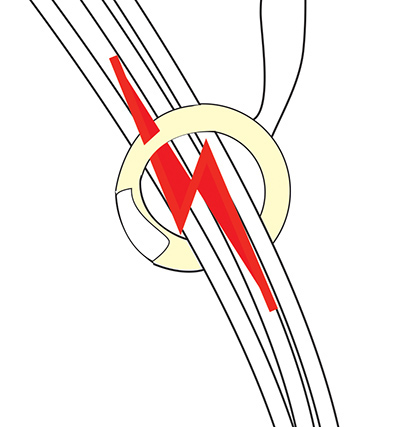

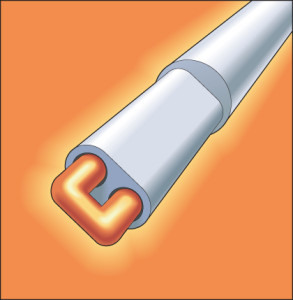

Current Sensing Technology

Skutt is one of the few brands that installs a Current Sensor in every KilnMaster Kiln. This allows you to read the Amperage of each section of the kiln as well as the Voltage and Voltage Under Load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair. This Saves Time and Money.

Prior to the use of these current sensors someone would have to come to your house and test the amperage and voltage inside the control box with live wires exposed. This system is Much Safer.

Sectional Design

Sectional Design is a good idea on so many levels.

Moving

Imagine trying to move a kiln into the basement or through a narrow door without being able to break it down into sections.

Repair

No more standing on your head in the kiln to replace those bottom elements or removing every brick in the kiln to get to the one you want to replace. Just remove the control box, unhook the buckles and place the section you want to work on on a table.

Replacement

We hope nothing really bad happens to your kiln … but … if it does, isn’t nice to know you can replace one bad section instead of the whole kiln?

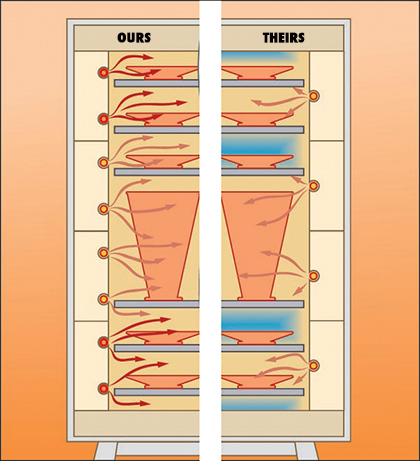

Balanced Elements

A large amount of the heat you lose in your kiln passes to through the lid and slab of your kiln. To compensate for this, Skutt directs more heat to these areas when they design the elements. The fact that we have twice the element grooves in our kilns gives us more design flexibility than some of our competitors.

It also gives you more loading options since it is always recommended to have at least one element radiating between each layer of shelves. Oh and by the way, twice the grooves means you get twice the amount of element wire, which means each element doesn’t have to work as hard, which means longer element life! Whew!

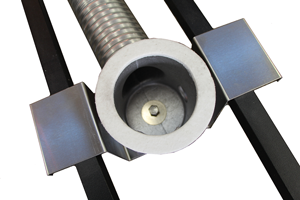

The Thermocouple

- Exposed Thermocouple equals faster reaction time and higher accuracy.

- Inexpensive, plus we give you an extra one when you buy your kiln.

- Easy and quick to replace.

- Type S (Platinum) Upgrades Available.

The Warranty

- Unlike most warranties, ours covers Parts AND Labor.

- Never Pro-Rated.

- Serviced by the most extensive, knowledgeable and talented distributor network in the industry.

- Backed by a company whose mission statement is “We help you make great things”. When your kiln is down, you can’t make great things.

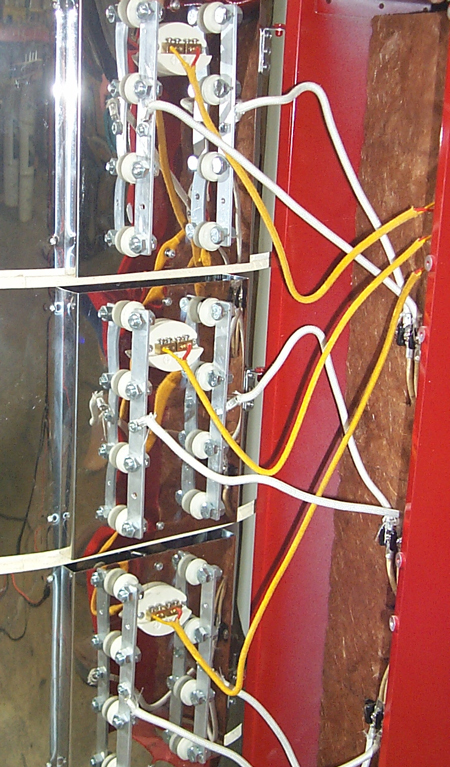

PK Power

One of the most important things you need in a large production kiln is power… and the KM1627-3 has it in spades!. An under-powered production kiln will fire slow and cause your elements to spend more time than necessary at high temperatures which can drastically reduce their useful life. Time is money, and when you are in business you can’t afford to waste either one.

The more than 23000 watts of power is delivered by industrial grade wiring and components that can more than handle it.

The elements are connected by a unique bus bar system make it very easy to replace the elements.

We offer a Cone 10 model as well as a low fire model (Cone 1) for companies that may have limited power available to them.

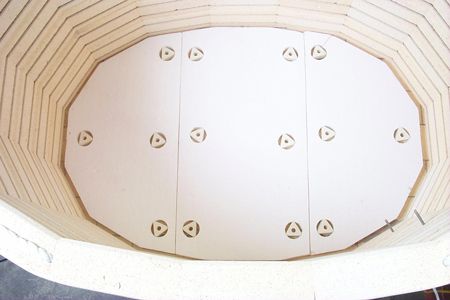

Longer Lasting Lids and Slabs

You ask anyone who has run an oval kiln for a period of time and they will tell you the most frustrating things to deal with are the lid and the slab. Big lids and slabs want to bend like a potato chip during the firing. This is caused by the surfaces on the inside of the kiln expanding greater than those on the outside. To help combat this, Skutt has done two things.

The first was to replace the traditional brick lid with an Engineered fiber lid that not only resists cracking, it is also lighter. The second thing we did was to insulate the bottom slab from the heat with a fiber insert. By reducing the temperature difference between the inside and outside surfaces we were able to drastically reduce the amount of cracking.

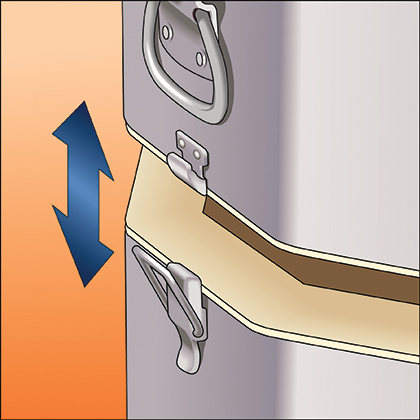

Cam Brace System

With a big oval lid you need to lid braces to support it. Prior to Skutt’s new lid brace design oval owners use to do what we affectionately called the lid dance. It seemed every time you released one lid brace with your free hand not holding the lid up, the other lid brace would fall back into it’s groove. You would then have to switch hands and pull it out of the groove only to see the other side fall back in…AARGHHH!

Skutt’s unique design works much like an extension ladder. Just lift the lid up until the cams on each side cover the locking notch and then lower the lid…AAAAHHHH!

And So Much More!

When you are buying a kiln, you are not just buying the equipment, you are also buying the service that comes before and after the sale. From the moment we cut that first brick to the day you open the box, to the day you are ready to retire it, our reputation is on the line and we take that very seriously. Get the whole story here.

Resource Links

Below you will find links to resources that are specific to this model:

KilnMaster Kiln Manual

KilnMaster Operation Video

| Model | Phase | Volts | Amps | Watts | Temp (F) | Cubic Ft | Opening (in) | Depth (in) | NEMA Receptacle | Ship Dims. (in) | *Ship Wt. (lbs) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Download a KM-1627-3PK 3 Inch Brick 1 Phase 240 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 1 Phase 240 Volts Product Spec Sheet | ||||||||||||

Download a KM-1627-3PK 3 Inch Brick 1 Phase 208 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 1 Phase 208 Volts Product Spec Sheet | ||||||||||||

Download a KM-1627-3PK 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet | ||||||||||||

Download a KM-1627-3PK 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet | ||||||||||||

Download a KM-1627-3PK 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet | ||||||||||||

Download a KM-1627-3PK 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet Download a KM-1627-3PK 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet | ||||||||||||

| KM-1627PKLF | 1 | 240 | 68 | 16300 | Cone 1, 2100 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

| KM-1627PKLF | 1 | 208 | 69 | 14300 | Cone 1, 2100 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

| KM-1627PKLF | 3 | 240 | 46 | 16300 | Cone 1, 2100 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

| KM-1627PKLF | 3 | 208 | 47 | 14300 | Cone 1, 2100 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

| KM-1627PK | 3 | 240 | 66 | 23600 | Cone 10, 2350 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

| KM-1627PK | 3 | 208 | 76 | 23600 | Cone 10, 2350 F | 18.5 | 46.00 x 31.00 | 27 | Direct Wire | 58 x 50 x 54 | 535 | |

KM-1027 kiln

Chamber Capacity

| Depth | Opening Width | Opening Length | Cu. ft. | Tea Bowls |

|---|---|---|---|---|

| 27 in | 46 in | 31 in | 18.5 | 99 |

Approximately 46 in. x 31 in. opening and 27 in. high: 18.5 cubic feet, 99 bowls.

Bowl, 6 inches in diameter and 3 inches high.

Contents List

Skutt Kilns should arrive fully assembled.

Packed with the kiln you will find the following items:

- Kiln Stand

- Slab Protecting Fiber Insert

- 15 – 2″ Posts (13 if drilled for vent

- Instructional Video

- Stand Feet

- Extra Thermocouple (unless Type S)

- 6 Peep Plugs

Buying Skutt Products

All Skutt products, with the exception of parts, need to be purchased through an Authorized Skutt Distributor. To locate a Distributor just click on the Distributor Finder icon below.

If you are looking to purchase a kiln, you may want to use the Build A Kiln tool first so you are absolutely sure you are ordering the correct kiln with all of the accessories and upgrades you want.

If you want to buy parts, you are welcome to purchase them directly from Skutt however your local distributor may have them in stock which would save you money on shipping. Use the Parts Finder Tool to pull up all the parts available for your specific kiln. If you want to order directly from Skutt call (503) 774-6000

If you are an Architect or contractor who is looking to Specify a particular model for future purchase, use the Build A Spec tool to generate a Specification Sheet.