Crystalline Glazes with Skutt Kilns

Why High-Fire Crystalline Glazing Needs the Right Ceramic Kiln

Skutt understands that creating high-fire crystalline glazes can be demanding on an electric kiln. Choosing the right ceramic kiln is essential for crystalline firing. This unique glazing technique requires a kiln with a significant power-to-size ratio, durable elements for high heat, effective thermal insulation, an accurate thermocouple, long-lasting relays, and a controller that supports custom programming.

The Skutt Production Kiln (PK) series is particularly well suited to repeated high-fire crystalline glazing, especially when outfitted with APM elements, a Type S thermocouple, and a touchscreen controller. For smaller firing needs, Skutt’s 1018-3, 822-3 or 818-3 are excellent alternatives with the above listed upgrades.

Skutt Production Kilns: Built for Power and Efficiency

Skutt’s PK line of ceramic kilns provide the extra power required to reach Cone 10 temperatures reliably. Designed to draw more amperage than a standard kiln, Skutt Production Kilns feature a higher power-to-size ratio, enabling the elements to work more efficiently because they don’t have to work as hard during each firing, which helps them last longer. A kiln that can reach peak temperatures faster also costs less to fire and yields more consistent glaze results.

Optimizing Kiln Elements for High Temperatures

All Skutt kilns are built with top-of-the-line Kanthal A-1 elements. Heating elements have a natural lifespan, and firing to Cone 10 temperatures will wear them out more quickly than firing to lower temperatures. For repeated high-fire crystalline programs, upgrading to APM elements will extend their lifespan. APM elements don’t draw more power or make the kiln fire hotter, but their manufacturing process allows them to withstand high heat exposure better.

APM elements are essentially standard Kanthal elements that have been ground, melted, and re-extruded into new wire. This additional processing gives the element additional dimensional stability, preventing it from sagging or collapsing after repeated high temperature firings. Elements are more likely to collapse when firing to or holding at high temperatures, which reduces their effective lifespan. An APM element can last about three times longer than a standard element when firing to Cone 10.

Thermal Insulation for High-Temp Firing Efficiency

Additional thermal insulation is key to efficiency at high temperatures. All of the Production Kiln models are built with energy saving 3-inch-thick walls, lids, and floors. This helps retain heat better than the standard 2.5-inch-thick walls of other models. More insulation means less heat loss. Elements that do not have to work as hard to reach and maintain peak temperatures will last longer.

Using a Thermocouple for Precise Temperature Control

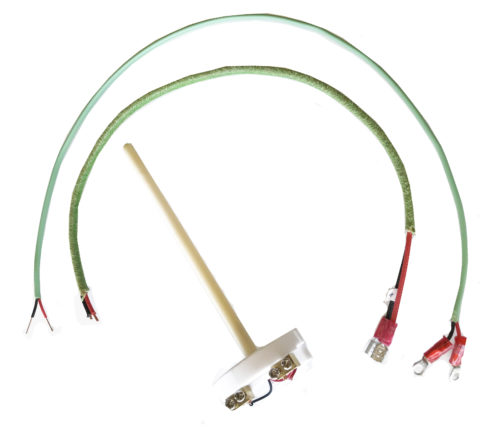

Crystalline glaze firing requires precision temperature measurements, and a quality thermocouple is essential for consistent results. A Type S thermocouple is a beneficial upgrade for frequent high temperature firings in any kiln, but is crucial to crystalline glaze firing, which requires precise temperature control. Most Skutt kilns are fitted with a standard Type K thermocouple, but nearly all Skutt kilns can be upgraded to Type S. A standard thermocouple can be fired to Cone 10, but it oxidizes and sheds black metal flakes, causing it to wear out quickly and need frequent replacement.

However, a Type S thermocouple is made of platinum and doesn’t wear out, even when fired to Cone 10. It doesn’t shed any metal flakes, has a working temperature rating of over 2900*F, is accurate to within +/- 0.25% of the temperature, and can virtually last forever, provided it isn’t physically damaged.

Type S thermocouples are more expensive than standard Type K thermocouples, but the precision, lifespan, and lack of shedding make them worth the price for crystalline potters. The only downside to a Type S thermocouple is its fragility. If the thermocouple is struck by a kiln shelf during loading or unloading, it can break easily.

Choosing Solid State Relays for Durability

All computerized kilns use relays to control power to the heating elements. Most kilns have mechanical relays with moving parts, but Skutt Production Kilns use solid state relays, which have no moving parts. This makes solid state more durable and quieter compared to mechanical relays, which make a clicking noise during operation. The life of a mechanical relay is measured by the number of times it turns on and off, which can be tens of thousands during its lifespan, eventually wearing out and needing to be replaced. Anyone who has fired a kiln knows that a relay failure in the middle of a glaze firing can ruin a perfectly good day.

Solid state relays, on the other hand, don’t tend to wear out over time. Crystalline firings with long holds at high temperatures put standard relays to the test with every firing. Using solid state relays, which have no moving parts to cycle power to the elements, means there is one less component likely to wear out and ruin a firing.

Advanced Programming with the KilnMaster Touchscreen

Crystalline firing requires unique programs to achieve specific glaze results, so having a computerized controller capable of setting up a complex program is critical. Skutt’s KilnMaster Touchscreen (KMT) controller allows users to program up to 36 custom programs, each with up to 16 individual segments. The large screen provides the option to view the entire program at once, making it much easier to confirm program details compared to a standard keypad controller.

Programs on a KMT touchscreen can also be edited during a firing, and segments can be skipped mid-firing if desired. The touchscreen controller is also Wi-Fi enabled and can be linked to the free KilnLink app for remote temperature monitoring.

Additionally, a premium KilnLink subscription can be purchased to log firing details for better historical record-keeping and maintenance. This premium subscription can also send text or email alerts to notify the user of an error or when the kiln has reached a desired temp.

Best Skutt Kilns for Small-Scale Crystalline Firing

If the larger firing chamber of the PK series kilns is too big for your needs, a custom KM1027-3 PK can be ordered, or the smaller KMT 1018-3, KMT 822-3 or KMT 818-3 would be a good choice for low-volume crystalline firing. Any of these models can be upgraded with APM elements, Type S thermocouple, and solid-state relays. They all have a very good power-to-size ratio and will hold up well to repeated high-temperature firings. If an even smaller test kiln is needed, the GlazeTech model is the go-to kiln. It has a excellent power-to-size ratio and can be upgraded with all the options, including a mini touchscreen controller. Whatever your crystalline firing needs, Skutt has a kiln option to help you make great things.

Joshua Rysted is a Kiln Technician at Skutt, and shares a studio with his wife Martha Grover, in Maine