GM-1214

Home > Glass Fusing Kilns > GM-1214

It’s Big!

This is the largest round top-fired glass fusing kiln we make. Want to make a bird bath…you can do it. Want to make a sink..you can do it! When you are not making large things, you can load a ton of small things in this kiln (okay maybe not a ton ,but a lot). This kiln is perfect for teaching and production studios.

Sophisticated, Yet Easy to Use

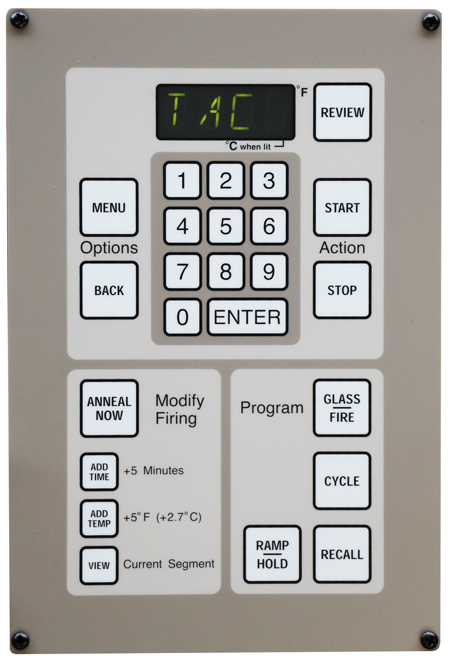

- The GlassMaster Controller is the only controller on the market with GlassFire Mode. GlassFire Mode allows you to run a program simply by entering the type of effect you want: Fuse, Tack Fuse or Slump and a speed based on the size and thickness of the project. It really is that easy and it works on most projects.

- If you prefer to write your own firing programs simply use the Ramp/Hold programming mode which can store up to 8 of your custom programs with up to 8 Segments. When you are ready to use one of your stored programs just load it and press start.

- Built in Diagnostics give you or our technicians the ability to diagnose kiln problems with just a few button presses.

- Active Keys allow you to make adjustments to the program while it is running based on a visual inspection. The Anneal Now key allows you to skip to the annealing phase of the program with a single key press. Add Time allows you to add 5 minutes to the final heating segment of the program if your project needs more time and Add Temp allow you to increase the temperature in the final heating segment if you want the glass to get hotter.

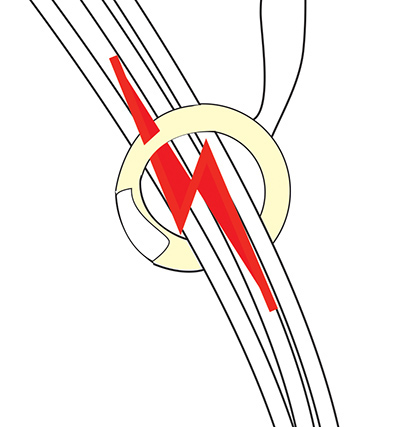

Current Sensing Technology

Skutt is one of the few brands that installs a Current Sensor in every GlassMaster Kiln. This allows you to read the Amperage of each section of the kiln as well as the Voltage and Voltage Under Load.

Now with the touch of a few buttons you can give those readings over the phone to your kiln repair technician so they can troubleshoot the problem and make sure they have the correct parts when they come out for the repair. This Saves Time and Money.

Prior to the use of these current sensors someone would have to come to your house and test the amperage and voltage inside the control box with live wires exposed. This system is Much Safer.

Balanced Elements

As most of you probably already know, glass is very susceptible to uneven heating. The more uneven the heat is in the kiln chamber, the slower you need to fire the kiln. Side fired kiln owners understand this, and are willing to trade the disadvantages of having to slow their programs down for advantages of being able to fire on multiple levels.

Our Studio Kiln Series have lid elements and side elements. This does not mean you can fire on multiple levels. The side elements are there to replenish heat on the bottom of the kiln. This not only keeps the shelf warm (which is important), it also provides for uniform heat top to bottom for artists working with deep molds and drop molds.

The Thermocouple

- Thin-walled inconel cover equals faster reaction time and higher accuracy.

- Easy and quick to replace.

The Warranty

- Unlike most warranties, ours covers Parts AND Labor.

- Never Pro-Rated.

- Serviced by the most extensive, knowledgeable and talented distributor network in the industry.

- Backed by a company whose mission statement is “We help you make great things”. When your kiln is down, you can’t make great things.

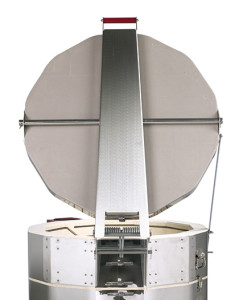

The Lid Lifter

- Standard on GM1214-3

- Lift 100lbs with ease!

- All stainless construction.

- Easy and safe to tension.

And So Much More!

When you are buying a kiln, you are not just buying the equipment, you are also buying the service that comes before and after the sale. From the moment we cut that first brick to the day you open the box, to the day you are ready to retire it, our reputation is on the line and we take that very seriously. Get the whole story here.

Resource Links

Below you will find links to resources that are specific to this model:

GlassMaster Kiln Manual

| Model | Phase | Volts | Amps | Watts | Temp (F) | Cubic Ft | Opening (in) | Depth (in) | NEMA Receptacle | Ship Dims. (in) | *Ship Wt. (lbs) | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

Download a GM-1214 3 Inch Brick 1 Phase 240 Volts Product Spec Sheet Download a GM-1214 3 Inch Brick 1 Phase 240 Volts Product Spec Sheet | ||||||||||||

Download a GM-1214 3 Inch Brick 1 Phase 208 Volts Product Spec Sheet Download a GM-1214 3 Inch Brick 1 Phase 208 Volts Product Spec Sheet | ||||||||||||

Download a GM-1214 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet Download a GM-1214 3 Inch Brick 3 Phase 240 Volts Product Spec Sheet | ||||||||||||

Download a GM-1214 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet Download a GM-1214 3 Inch Brick 3 Phase 208 Volts Product Spec Sheet | ||||||||||||

| GM-1214-3 | 1 | 240 | 42 | 10000 | Cone 0, 1800 F | 5 | 28.00 x 28.00 | 13.5 | 6-50 | 42 x 45 x 33 | 285 | |

| GM-1214-3 | 1 | 208 | 48 | 10000 | Cone 0, 1800 F | 5 | 28.00 x 28.00 | 13.5 | 6-50 | 42 x 45 x 33 | 285 | |

| GM-1214-3 | 3 | 240 | 29 | 10000 | Cone 0, 1800 F | 5 | 28.00 x 28.00 | 13.5 | 15-50 | 42 x 45 x 33 | 285 | |

| GM-1214-3 | 3 | 208 | 29.4 | 10000 | Cone 0, 1800 F | 5 | 28.00 x 28.00 | 13.5 | 15-50 | 42 x 45 x 33 | 285 | |

Chamber Capacity

| Depth | Opening Width | Opening Length | Cu. ft. |

|---|---|---|---|

| 13.5 in | 28 in | 28 in | 5 |

Approximately 28 in. x 28 in. opening and 13.5 in. high: 5 cubic feet.

There are no upgrades available for this kiln.

Contents List

Skutt Kilns should arrive fully assembled.

Packed with the kiln you will find the following items:

- Kiln Stand

- Stand Feet

- Peep Plugs – attached to the kiln stand, enough to fill each peephole on your particular model.

Buying Skutt Products

All Skutt products, with the exception of parts, need to be purchased through an Authorized Skutt Distributor. To locate a Distributor just click on the Distributor Finder icon below.

If you are looking to purchase a kiln, you may want to use the Build A Kiln tool first so you are absolutely sure you are ordering the correct kiln with all of the accessories and upgrades you want.

If you are an Architect or contractor who is looking to Specify a particular model for future purchase, use the Build A Spec tool to generate a Specification Sheet.