Glass Blowing Kilns

Select Your Kiln Type

Determine Capacity Needed

First, you need to find

out if the chamber of the kiln will be large enough to fire the pieces

you produce. The chart below lists the chamber sizes for each model.

The 3 things to consider when choosing the necessary chamber size are:

![]() What are the dimensions of the largest piece you will want to fire?

What are the dimensions of the largest piece you will want to fire?

![]() What is the

maximum volume of material that you will need to produce in a specific

time frame?

What is the

maximum volume of material that you will need to produce in a specific

time frame?

![]() How do feel

your needs will grow in the next 5 years?

How do feel

your needs will grow in the next 5 years?

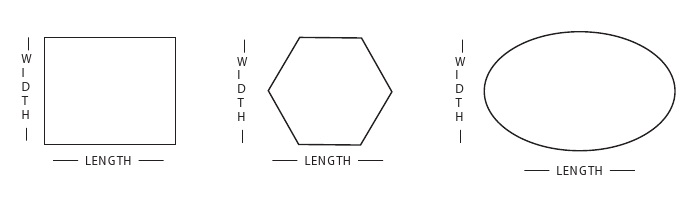

Use the following image as a reference for dimensions:

Kiln Chamber Dimension

What is the smallest acceptable chamber width:

What is the smallest acceptable chamber length:

What is the smallest acceptable chamber depth:

Determine Your Available Power Supply

The next step is to find a kiln that will operate on the electrical service

of your building. Ordering a kiln that does not match your electrical service

can be very frustrating and expensive to correct.

Most people will need to have an electrician install the wire from the circuit

breaker panel to the wall receptacle as well as the receptacle. It is also

wise to have the electrician verify voltage, amperage and phase when he visits

on-site to estimate the job.

Learn More About Voltage. Click

Here

Learn More About Amperage. Click Here

Learn More About Phase. Click

Here

Refer to the Refined List to make sure the parameters you are selecting in the current step are possible

I want my kiln wired for the following voltage :

240 Volts 208 Volts 120/208-240 Volts 115 VoltsMy maximum amperage available for a new dedicated breaker is:

30 Amps 40 Amps 50 Amps 60 Amps 70 Amps 80 Amps 90 Amps 100 AmpsI have these power supply phases available:

1 3 1 and 3Determine the Firing Temperature Needed

Now we need to find a kiln that will fire to a temperature that meets, and preferably exceeds, the temperature requirements of the materials you will be working with.

Kilns are designed to fire to a variety of temperature ranges. Materials such as porcelain and stoneware require the kiln to reach temperatures up to Cone 10 (2350 F) and materials such as glass only require the kiln to reach less then 1600 F. Whenever possible you should choose a kiln that exceeds your firing temperature needs. The use of 3" brick, the voltage and the phase of a kiln model can sometimes affect its maximum rating. If you are firing regularly to Cone 6 (2250 F) or above, we highly suggest you buy a kiln that is rated to Cone 10 (2350 F). Production Kilns, referred to as "PK" kilns, are specifically designed for the high fire production studio.

What is the maximum firing temp you need?

2100 F 2185 F 2250 F 2300 F 2350 F